Construction

Learn More

EnviroHoard™ 2.4

The go-to choice in our net-zero hoarding range, EnviroHoard™ 2.4 has been designed in accordance with the industry standard height of 2.4m.

It connects seamlessly to our EnviroBlok for easy, no-dig setup. Need flexibility? EnviroHoard™ 2.4’s modular design means that you can adapt the system to any layout and reconfigure as needed. Speedy installation, adjustments and removal mean that you can maximise efficiency and keep your project on track.

Looking for extra security or height? Our EnviroHoard SHEILD™ and EnviroHoard GOLIATH™ products are designed to meet the needs of your project.

EnviroHoard™ SHIELD

Need extra protection for your site? EnviroHoard™ SHIELD lets you mix solid and mesh panels for ultimate control and additional height. Choose a 3.0m solid panel or a 2.4m solid panel with a 0.6m mesh extension reaching heights of up to 3.0 metres.

Our clever design adds height without installation hassles. It’s also TWF-compliant and is suitable for the UK’s 3 wind zones.

Don’t forget, EnviroHoard™ SHIELD integrates seamlessly with our enhancements including security upgrades and lighting, keeping your site protected day or night.

EnviroHoard™ GOLIATH

Towering at 3.6m, EnviroHoard™ GOLIATH is built with the same quick, no-dig installation as our entire EnviroHoard™ range. Choose 3.6m solid panels or 2.4m solid panels with an additional 1.2m steel mesh extension. Using the same innovative EnviroBlok as the rest of the range, EnviroHoard™ GOLIATH complies with TWf2012 and UK wind zones, ensuring unmatched structural integrity.

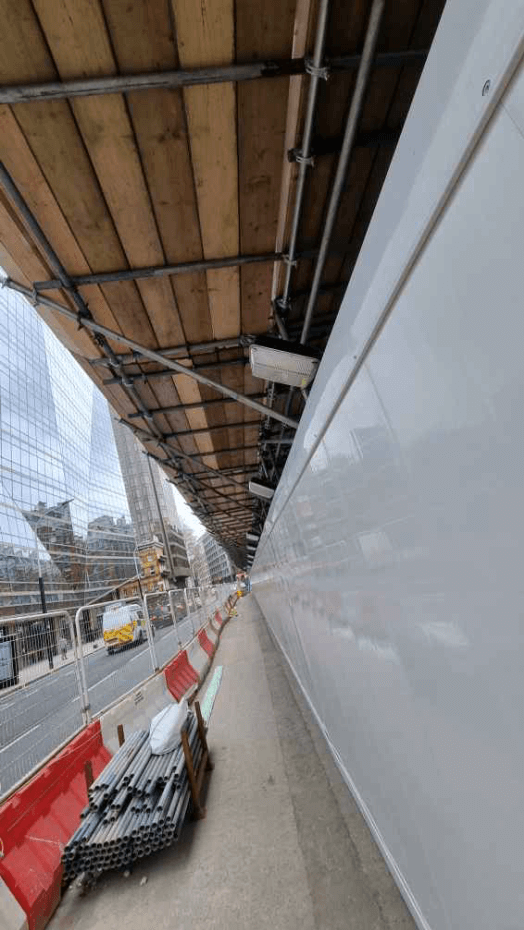

EnviroHoard™ SCAFFOLD

Introducing the UK’s first net zero hoarding system for scaffold encasement: EnviroHoard™ SCAFFOLD. Designed for towers and straight scaffold runs, EnviroHoard™ SCAFFOLD can reach impressive heights of up to 7m without compromising on strength or durability.

EnviroHoard™ SCAFFOLD seamlessly integrates with the rest of the EnviroHoard™ range using tailor-made bracket extensions and EnviroBlok technology. The system is TWf2012 compliant, available in any RAL colour, and can be customised for distinctive branding.

Enhancements

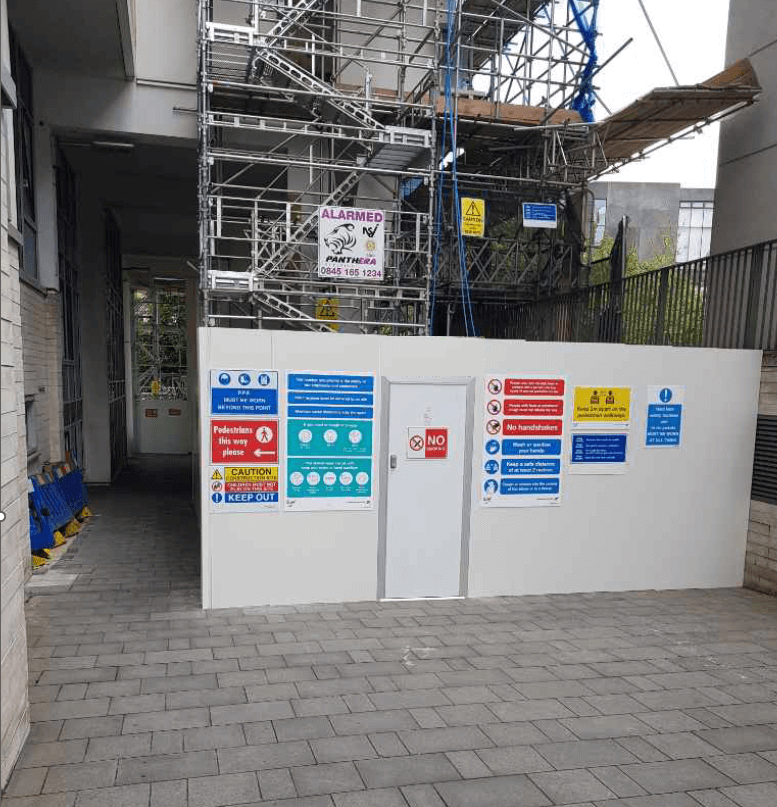

Enhance your construction site and address common issues with Panthera Group’s cutting-edge enhancements for EnviroHoard™ and EnviroFence™ systems.

Pavement Protection and Lighting

Our systems include provisions for heavy-duty cable support brackets, accommodating armoured 110v security cables. This ensures secure power distribution across the project area. Additionally, the designs feature integrated lighting brackets, supporting mains-powered or mains-free bulkhead lights. This strategic placement reduces light pollution while maintaining optimal visibility, and helps keep cables tidy behind the hoarding.

Security Upgrades

Enhance security with Single Roller, Double Roller, and Aluminium enhancements for an extra layer of perimeter protection. These upgrades bolster the defence against unauthorised access. The systems are also compatible with mains-powered or mains-free electronic fence security alarms, ensuring continuous surveillance.

All enhancements are available across our product range, including the 2.4m, 3.0m, 3.6m heights, and bespoke designs.

EnviroHoard™ EPulse electro-fence system

Designed to detect and deter trespassers, EnviroHoard™ EPulse is an optional security enhancement that seamlessly integrates with any EnviroHoard™, EnviroFence™, traditional hoarding systems and CraneSAFE™, or can be used as a stand-alone fence.

EPulse is a 10,000 volt shock and sounding alarm that boasts the combined power of a physical deterrent and instant alarm generation. The system is safe and legal to use, cost-effective, and allows for 24-hour monitoring and response. Powered by solar, EPulse is a sustainable security solution that can be used to secure almost any site – with or without power – nationally.

EnviroHoard™ featuring Clean Air by RESYSTEN

Thanks to a partnership with Clean Air by RESYSTEN, our net zero verified EnviroHoard™ system can improve air quality where it is installed.

The Clean Air by Resysten coating works wonders on almost any surface, fighting both indoor and outdoor pollution. In a process called photocatalysis, the photocatalytic nano-coating utilises titanium dioxide (TiO2), which when hit with light, breaks down atmospheric pollutants and organic compounds. In addition to a high NOx removal rate, cleaner surfaces, and reduced odours, Clean Air by Resysten offers patented binding technology, and a 12-month surface performance from just one application.

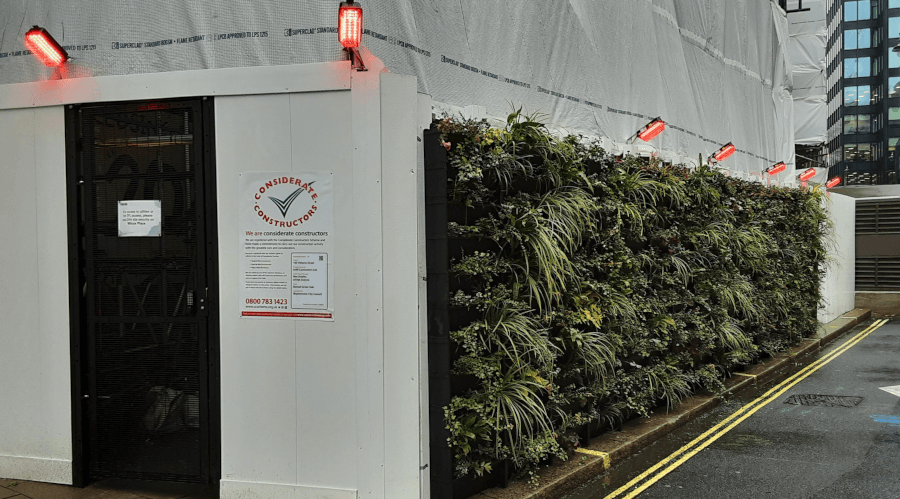

Enquire NowBranding

EnviroHoard™ is not just an excellent way of securing your construction site, it also provides an opportunity to showcase your project or brand identity. Showcase your carbon savings and environmental commitment with EnviroHoard™.

Choose from a spectrum of choices, including extruded or sprayed corporate colours, PVC-free graphics, and even living wall installations.

EnviroHoard™ is a no-dig, modular hoarding system which utilises low carbon blocks with cast-in fixing points. This makes installation much faster and safer - on an average installation, the EnviroHoard™ system takes half the time to install compared to traditional plywood hoarding.

EnviroHoard™ was invented with the goal of creating a hoarding system that offers reduced embodied carbon and saves trees from being cut down for use in construction sites. Over an average two-year project, 100m of EnviroHoard™ is around 70% lower embodied carbon than traditional plywood hoarding. When you choose this system, you save an estimated 8.7 trees from being needlessly cut down.

If your hoarding is going to sit on a public footpath or road then yes, you will need to apply for a hoarding licence from the local authority. Hoarding installed on private land does not require a hoarding licence.